Packaging machine is an indispensable equipment in the production and processing of organic fertilizer. Judging from the sales and use of full-automatic packaging machines in the current market, it can be proved that the development of fertilizer packaging machines has been recognized by many fertilizer enterprises.

Of course, the strength of production enterprises in this field is also an important factor whether the development of automatic packaging machine can achieve the current achievements. Fertilizer packaging machine provides the most basic guarantee for the technical improvement of organic fertilizer production process, so as to have high-quality organic fertilizer products.

Whether it is the screened compost powder or the organic fertilizer particles processed by the fertilizer granulator, the operator only needs to put the bags into the bags one by one and take out part of the equipment at one time. The mechanical grab of the equipment will automatically take out the bag, print the date, open the bag, Send a signal to the measuring device, measure the blanking and seal the output.

Customers can also add detailed functions such as emergency stop, automatic card entry, abnormal discharge and so on according to the packaging requirements of organic fertilizer products. The whole process of organic fertilizer machine packaging does not need manual operation, which effectively improves the production efficiency of chemical fertilizer enterprises and saves labor costs. Administrative expenses have greatly reduced costs.

Tag: Organic Fertilizer Production

Organic fertilizer production equipment application fields

Organic fertilizer production equipment uses pig manure, cow manure, chicken manure and other livestock manure as raw materials to produce organic fertilizer. When chickens, pigs, sheep and other livestock feed, due to the weak digestion ability, 75% of the nutrients in the feed are discharged with the feces, which contain nitrogen, phosphorus, potassium, organic matter, amino acids and protein.

For example, organic matter beneficial to soil and crops, so many people use organic fertilizer equipment to make these fertilizers into organic fertilizer for secondary utilization.

Advantages of organic fertilizer production equipment:

1. It is applicable to a wide range of raw materials. The organic fertilizer processing equipment is not only suitable for livestock manure, but also suitable for the fermentation of peat, sludge, lignite, straw, corn flour, soybean meal and grass meal to produce mixed feed particles.

2. The organic fertilizer production equipment has high efficiency and is fully automated. For example, in the fermentation process, just put the raw materials, auxiliary materials, drivers and other materials into the fermentation equipment and press the button to automatically complete the fermentation without manual turnover, doubling the fermentation time. Shorten the production time of organic fertilizer.

3. The complete organic fertilizer manufacturing equipment with high output includes fermentation equipment, drying equipment, granulation equipment, dehydration equipment, etc., with a production capacity of 30000 tons and an annual fecal sewage treatment capacity of nearly 80000 cubic meters. For granulation equipment, we recommend drum granulation.

More detailed info, welcome go to https://www.fertilizer-plants.com/

Powder Fertilizer Production Basis

There are two kinds of organic fertilizer: granular and powdery. The processing degree of products is different, the market situation is different, and the processing cost and profit are also different. The processing of powdered organic fertilizer is relatively simple.

The following mainly introduces the advantages of powdered organic fertilizer and fertilizer making machine.

1.Advantages of powdered organic fertilizer

Powdered organic fertilizer is an organic fertilizer without granulation and drying. It occupies most of the market share.

Compared with granular ecological organic fertilizer, powdered organic fertilizer production line has the advantages of small investment, low production cost, less nutrient diversion loss in the processing process, low price and less ecological pollution. It is generally accepted by plantations, orchards and orchards.

Vegetable base. The disadvantage is that the appearance of the product is not beautiful enough and is not suitable for machine broadcasting.

2. Powdered organic fertilizer production equipment

The production process of organic fertilizer powder is relatively simple. Fertilizer production machinery mainly includes: organic fertilizer dumper, forklift, batching machine, shredder and screening machine (drum screening machine or vibrating screening machine).

If you want to change the organic fertilizer production line to process granules in the later stage, you can add drum granulator, organic fertilizer granulator, flat mold granulator, disc granulator, drying and cooling system and other granulation equipment.

The equipment shall be connected with the belt conveyor to form a complete production line:

1. A group of belt conveyors above the crusher are connected with the screened large raw materials.

2. The belt at the top of the screening machine is connected with the fermentation raw materials.

3. The belt under the screening machine is connected with the screened finished material, and the finished material is sent to the processing position for weighing and packaging.

4. The warehouse needs conveyor belt for loading.

More detailed info, welcome go to https://fertilizerplantequiment.com/compost-production-equipment/

Bio fertilizer production what machines can be used for

The organic fertilizer flat mold granulator adopts microbial fermentation technology to produce deodorized, sterile, high fertilizer efficiency, non root burning and non seedling burning organic fertilizer from livestock and poultry feces, urban garbage and other feces.

This machine is used for grain fields, fruits, vegetables and flowers. It is applicable to the technical transformation of organic fertilizer production line in new plant or original compound fertilizer plant.

Main performance characteristics of organic fertilizer flat mold granulator

The press roll of this machine adopts inclined wheel. The speed of both ends of the template is the same as that of the inner and outer ring of the template, there is no dislocation friction between the wheel and the mold, the resistance is reduced, the kinetic energy loss is reduced, and the service life of the mold is prolonged.

This is the main difference from similar die equipment. At the same time, the technology adopted by organic fertilizer granulator is the most advanced technology today. The press rollers of the flat molding granulator are evenly arranged and run smoothly, eliminating the easy feeding of the ordinary flat molding roller.

The organic fertilizer flat mold granulator adopts the central pressure regulating structure to adapt to different materials and ensure the pressing effect. The pressing die of sawdust and corn straw needs a lot of pressure. Among the similar granulation equipment, the drum part is the core part of the whole equipment.

The use of high-quality alloy steel improves the service life of the drum of organic fertilizer granulator.

The bio organic fertilizer flat molding granulator is equipped with a suitable pelletizer on the basis of the fertilizer granulator, so that the cylindrical particles can form balls at one time without returning particles, with high granulation rate, good strength, beautiful and applicable. It is an ideal equipment for biological fertilizer granulation.

More detailed info, welcome go to https://fertilizerplantequiment.com/in-vessel-composting-equipment/

Potassium chloride granules production with pan granulator

In the production of potassium chloride granular fertilizer, the powder can be granulated by disc fertilizer granulator. The particles produced by disc granulator are spherical and have good strength. It can be widely used in agricultural production.

In the granulation process of disc fertilizer granulator, adhesive needs to be added to form the particles. The binder can be compounded by ordinary inorganic minerals in a certain proportion. When potassium chloride is granulated, the adhesive has synergistic effect.

When using adhesive granulation, it has a good effect on granulation rate and particle strength. Potassium chloride is granulated by disc fertilizer granulator, and the particles are spherical.

Process flow of NPK fertilizer production line

NPK fertilizer production line deals with potassium chloride fertilizer. First, all raw materials are mixed through the batching system and crushed to the appropriate particle size through the chain mill. The disc fertilizer granulator makes the powder into particles.

After drying and cooling, the potassium chloride particles are coated with a protective film through a fertilizer coating machine to complete the particle processing of potassium chloride.

Disc fertilizer granulator NPK fertilizer production line

When applying potassium chloride, attention should be paid to the appropriate potassium application period.

The application period of general potassium fertilizer should be early or not late, and it should be used as base fertilizer and early recovery period. When the application amount of potassium fertilizer is small, it can be used as base fertilizer at one time.

When the application amount of potassium fertilizer is large or the soil texture is light, the application effect of base fertilizer and topdressing is better.

Soil nutrients and fertilization should also be considered when determining the appropriate application period of potassium fertilizer.

In the soil with serious potassium deficiency, the middle soil potassium fertilizer should be fully applied with potassium fertilizer as the base fertilizer, appropriate organic fertilizer as the base fertilizer, combined with topdressing.

Pay attention to the application method of potassium chloride. The centralized application of potassium fertilizer is conducive to improve its utilization rate and achieve good results. However, direct contact with seeds or seedlings is not recommended. For general crops, the combination of soil fertilization and foliar fertilization can be adopted.

More detailed info, welcome go to https://organicfertilizermachines.com/npk-fertilizer-manufacturing-process/

How to use disc granulator for organic fertilizer production?

During the daily use of the disc fertilizer granulator, the rotation of the disc should be checked frequently.

According to the situation of organic fertilizer production line or compound fertilizer production line, the disc speed should be controlled within a reasonable range to avoid the impact of disc speed on product particle size.

First startup and operation of disc fertilizer granulator

1. Before starting the disc granulator, increase the temperature for about 40 to 50 minutes. Raise the temperature to the extent that the motor V-belt can be pulled by hand; Continuously pull the motor V-belt eight to ten times in the normal working direction.

Then continue heating for about 10 minutes, and then start the machine, but continue heating, because normal production needs to continue heating; Adjust different temperatures according to different characteristics of plastics.

2. During the normal operation of the granulator, the temperature of the granulator shall be kept stable, neither high nor low. Keep the temperature near the pores until the head temperature is about 200 ℃.

3. Feed evenly and add enough. The feed speed shall be properly matched with the feed speed of the machine. Otherwise, the mass and output of particles will be affected.

4. During shutdown, the main engine shall be completely cut off. The head plug (with wrench) must be removed. Preheat separately before next use.

In addition, special attention shall be paid to the inspection of the transmission part of the disc granulator, i.e. the transmission gear.

The rotation of the transmission gear is completed with the help of lubricating oil. Therefore, in the process of gear operation, regularly check its lubrication and add lubricating oil and grease to the gear appropriately to ensure good lubrication of the gear and make the operation of the granulator more stable and reliable.

In addition, our company also produces other fertilizer granulators, double roll extrusion granulators, drum granulators, conveyors, dryers, particle screening machines, packaging machines and other products. For more fertilizer equipment information, please contact us.

Fertilizer Production with Dry Granulation Equipment

Organic-inorganic compound fertilizer can not only provide comprehensive nutrition for crops, but also increase and renew soil organic matter, promote microbial reproduction, improve soil physical and chemical properties and biological activity, and reduce environmental pollution. Want to make compound fertilizer by your own fertilizer project, welcome go to https://fertilizergranulatormanufacturer.com/compound-fertilizer-granules-manufacturing-plant-cost/

With the increase of crop yield per unit area and the increase of chemical fertilizer application, soil degradation is becoming more and more serious. Excessive application of chemical fertilizer, especially nitrogen fertilizer, is easy to cause soil nutrient imbalance, soil erosion, secondary salinization, soil acidification and other problems, resulting in the continuous decline of soil fertility.

Organic-inorganic compound fertilizer is a high-quality fertilizer for the production of green and pollution-free agricultural products. The yield of organic-inorganic compound fertilizer is about 10% higher than that of single chemical fertilizer.

Flat die extrusion granulator is suitable for granulation of organic-inorganic compound fertilizer. Organic and inorganic raw materials can be made into organic fertilizer. It is the key equipment in the production process of organic-inorganic compound fertilizer.

Production technology of organic-inorganic compound fertilizer

In the production process of organic-inorganic compound fertilizer, when the fertilizer particles are extruded, there is no need to spray water before granulation, and there is no need to dry and cool after granulation. The granulation rate of flat die extrusion fertilizer granulator is more than 90%.

Because the base fertilizer is not heated, nutrients will not be lost.

Moisture control of flat die extrusion fertilizer granulator

Because there is no drying equipment in the production process of organic-inorganic compound fertilizer, controlling the moisture of appropriate raw materials and controlling the moisture of finished fertilizer within the standard range is the key to the production of flat mold granulator.

In the production of fertilizer granulator, the dosage of calcium, magnesium and phosphorus fertilizer should be strictly controlled. Before granulation, calcium superphosphate should be added to calcium magnesium phosphate fertilizer to neutralize the raw materials.

More detailed info of different types of fertilizer machines, welcome go to https://fertilizergranulatormanufacturer.com/

Deodorization method in organic fertilizer production process

The organic fertilizer production line is used to produce organic fertilizer, organic waste, sludge, straw, sawdust, food processing waste and other materials, which will produce all kinds of peculiar smell if they are piled up in one place for a long time.

These wastes are treated in the organic fertilizer manufacturing process to become valuable organic fertilizer and contribute to agriculture.

How does the organic fertilizer equipment deodorize these organic wastes?

Here is a brief introduction.

There are many methods to eliminate odor, such as

1. Adsorption method;

2. Air dilution method;

3. Ozone oxidation method;

4. Masking method;

5. Chemical treatment;

6. Water washing method;

7. Combustion mode;

And plasma and biological deodorization.

The above methods are one of the deodorization methods in the process of organic fertilizer production. Each organic fertilizer production line uses different methods, and each method has its own deodorization method and system.

In the process of producing organic fertilizer, it is necessary to use a dumper for fermentation treatment, so that these materials can remove peculiar smell and harmful substances through the deodorization system. Therefore, the deodorization system of organic fertilizer production line is an essential detail.

More detailed info on organic fertilizer production, welcome go to https://organicfertilizermachines.com/organic-fertilizer-production-line/

Dryer Function in Quality Organic Fertilizer Prodcution

After the production and processing of organic fertilizer, the storage of fertilizer shall be considered. How to make the fertilizer effect non-volatile, the most important consideration process is actually a link in the manufacturing process of organic fertilizer, that is, the drying of organic fertilizer. After drying by the organic fertilizer dryer, the water in the organic fertilizer particles is evaporated, and the dried particles can be stored in the warehouse for a long time.

The role of organic fertilizer dryer is not only here, but also the granulation results of inspection equipment. The fertilizer particles treated by the drum granulator enter the drying process. After drying, the particles are full and round, but will not crack and break. If there are too many cracks in the dried fertilizer particles, the proportion of fertilizer shall be adjusted during the previous fermentation granulation.

Drum dryer plays an important role in fertilizer production. It is composed of air cylinder, gear, pinion, stop roll, traction roll, front roll ring, rear roll ring, unloading part, lifting plate, reducer, motor, hot air, etc. The utility model is composed of a channel, a feeding trough, a furnace body, etc. NPK fertilizer production process can be equipped with multiple hot blast stoves when the production capacity is large, which is simple and easy to operate, and the production effect is also very good.

Fertilizer production process dryer

Adding cooling system can greatly improve the production effect of fertilizer. SX fertilizer equipment company, our products include: chicken manure dryer, rotary dryer, cow manure dryer, pig manure dryer, organic fertilizer dryer and NPK compound fertilizer dryer. The production process can be adjusted and the size of dryer can be customized according to the needs of chemical fertilizer production line.r

Must Know Knowledge on Organic Fertilizer Production

SX fertilizer equipment manufacturer introduces the production process and process of chemical fertilizer in large chemical fertilizer plant. Friends who want to build a fertilizer plant can refer to it.

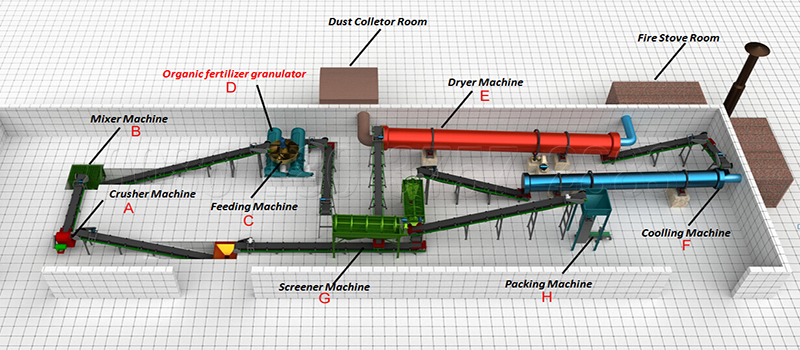

Organic fertilizer production process

1. After mixed fermentation of strains and raw materials, composter is used in the fermentation process. Fermented compost can provide nutrients and improve soil properties, especially for sandy soil, clay and saline soil.

2. The rotten raw materials are crushed, screened and transported to the deep processing workshop by elevator.

3. The fertilizer is mixed by the raw material mixer and then enters the fertilizer granulator for granulation.

4. Next, the pellet fertilizer is sent to the granulation equipment for grinding.

5. The rounded particles reach the drying cylinder through the conveyor belt. The dried particles are then conveyed to the cooling drum through the conveyor belt for cooling.

6. The dust generated during drying and cooling enters the dust removal equipment for dust removal through induced draft. The cooled particles are then conveyed to the screening machine by the conveyor belt.

7. The screened particles enter the quantitative packaging equipment for packaging through the conveyor belt to become finished fertilizer.

Organic fertilizer production process

Equipment selection of NPK fertilizer granulator

There are many kinds of fertilizer processing equipment in the above process, such as granulation.

Different models of NPK fertilizer granulator are suitable for different processing processes, including disc granulator, drum granulator, drum extrusion granulator, etc. When selecting production equipment, fertilizer plants should consider their own plant planning, expected annual output, types of raw materials, etc., which are related to how to select the most appropriate equipment and ensure the maximum income.

Matters needing attention

Finally, the fertilizer granulator equipment manufacturer reminds you to consider the sales path of raw materials and fertilizers. Organic fertilizer raw materials that can be considered include crop straw, green fertilizer, weeds and other plant materials, as well as feces and sludge. Attention should be paid to whether the raw materials of livestock and poultry feces contain hormone residues and excessive heavy metals. The selection of bacteria should pay attention to the activity of bacteria and the number of useful live bacteria. In terms of marketing, we must investigate the local fertilizer demand and convenient transportation.

More details on organic fertilizer production, welcome go to https://organicfertilizermachines.com/

Organic Compound Fertilizer Production

The composition of organic fertilizer is complex, and rational application is very important. Fertilizer granulator equipment manufacturers suggest that we pay attention to the following two points.

1. Organic fertilizer should be fully decomposed before application. If some animal manure, such as pig manure, cow manure and sheep manure, is directly applied to the soil without fermentation and decomposition, the decomposed organic fertilizer in the soil will be decomposed and fermented by microorganisms, and the ammonia produced is easy to cause crop root burning, and some will breed weeds and spread diseases and pests.

We advocate using a dumper to fully ferment manure before application. After the compost is wetted with water, it is put into the fermentation tank to make the temperature reach 35-40 ℃. When feces are fully fermented at high temperature, it can kill insect eggs and weed seeds in compost, which is safer and more effective.

2. Organic fertilizer should not be too thick or applied too much. Especially when fertilizing dry land crops, if organic fertilizer is applied directly between rows or near the roots of crops, the concentration around the roots is too high due to the small water holding capacity of dry soil.

After the root system contacts the fertilizer pile, it will cause physiological water loss of crops and form reverse osmosis. Crops not only do not absorb nutrients, but also make water and nutrients in roots exude, resulting in poor growth or withering of crops, but water loss and dead seedlings cause soil nutrient imbalance.

The fertilizer made by NPK fertilizer manufacturing process can not alleviate soil problems, while organic fertilizer plays a great role in soil fertilization.

Therefore, organic fertilizer should be used as the base fertilizer, evenly mixed in the soil and integrated with the soil. When applying organic fertilizer in the growth period, ditch application or hole application should be adopted. Do not spread the pesticide on the ground. Foliar vegetables generally should not be sprayed with high concentration liquid organic fertilizer as foliar fertilizer.

Machine Selection Tips for Organic Fertilizer Production Manufacturers

With the improvement of living standards, people’s demand for machinery and equipment is increasing, and their dependence on machinery is also gradually increasing, which brings pressure to the development of organic fertilizer production equipment.

In the process of fertilizer production, in order to ensure the safety and operation of the production line, operators need to strictly require themselves to operate the equipment correctly. So how should we operate correctly in the operation of organic fertilizer production line? SX company, a large fertilizer equipment manufacturer, provides you with suggestions.

Requirements for safe operation of organic fertilizer production line

1. Relevant personnel operating organic fertilizer equipment shall receive professional training first and take up their posts only after passing the training.

2. As workers operating organic fertilizer equipment, they should first standardize their working attitude. Because correct operation is closely related to everyone’s safety, we must not be careless in the operation process, otherwise the materials may be damaged and personal safety may be endangered.

3. Organic fertilizer equipment shall be placed in a reasonable position, and attention shall be paid to ventilation and ground wire. When it is found that it cannot be operated, the workshop production shall be stopped immediately, and the problems shall be found out and handled.

4. Clean the machine in time after using the equipment, especially NPK fertilizer granulator. Regular maintenance of equipment appearance and smooth parts can ensure production and quality, and then bring economic benefits to the company.

5. The complete set of organic fertilizer production equipment shall be installed on the horizontal concrete foundation, especially the large equipment such as drum granulator, drum dryer and cooler shall be fixed with anchor bolts.

Pay attention to the verticality between the main body and the horizontal plane during installation. Configure the power cord and control switch according to the power of the equipment. No load commissioning shall be carried out after passing the inspection, and production can be carried out only after the commissioning is normal. More detailed process, go to https://organicfertilizerplants.com/organic-fertilizer-production-process/

Organic Fertilizer Granulation Process Know How

The manufacturing process of organic fertilizer is mainly to screen and magnetic separate the organic waste with a water content of about 30% ~ 35% after fermentation and decay to make a round grain organic fertilizer, add functional bacteria to produce biological organic fertilizer, and add nitrogen, phosphorus and potassium (the total nutrient content is less than 15%) to produce organic and inorganic fertilizers.

After the fermented organic waste is screened by magnetic separation, the raw materials containing binder and other compatible components are measured according to the proportion requirements, and then lifted by bucket elevator to multi-dimensional high-efficiency mixer for rapid mixing.

The mixed material slides out of the mixing bin and is continuously and evenly sent to the extrusion granulator by the disc feeder to make cylindrical particles; The cylindrical particles are polished into spherical particles by the circular particle polishing and setting machine and formed by the belt.

The machine is sent to the drying, cooling and screening machine (three in one model). The particles are dried at low temperature and large air volume (≤ 65 ℃) in the front section of the drying cooling screening machine, and then enter the cooling section for air cooling. After sufficient cooling, the materials enter the screen installed at the end of the cylinder.

The screened finished product particles are transported to the finished product silo by the elevator and measured and packaged by the packaging system; The screened large particles are crushed and returned to the mixed granulation system; The screened small particles (basically without powder) can be made into small packages and sold directly. Get more details on the granulation process, go to https://www.fertilizer-plants.com/granulator-machine-for-fertilizer/

Quality organic fertilizer production from plant ash

Plant ash is the residue of firewood after combustion. It belongs to alkalinity. The main component is potassium carbonate (K2CO3) which can be used as fertilizer. Before the widespread use of chemical fertilizers, agricultural plant ash refers to the ash produced after burning and eating by mountain grass, straw and branches (excluding the ash produced by coal).

The production of plant ash fertilizer is usually stacked with a layer of plant ash and used after several months of maturity. In industry, plant ash is also used as the main raw material of biological fertilizer project to process biological organic fertilizer.

Plant ash shall not be mixed with other fertilizers during storage. Some farmers are used to putting ash in puddles and mixing it with organic fertilizer and straw, which is very wrong. Because the ash is alkaline, it will cause the volatilization of nitrogen in organic fertilizer and reduce fertilizer efficiency. Such treatment will not only waste fertilizer, but also pollute the environment.

Ashes must be applied separately. Plant ash cannot be mixed with organic farm manure and ammonium nitrogen fertilizer to avoid nitrogen volatilization loss, nor can it be mixed with phosphorus fertilizer to avoid phosphorus fixation and reduce the use efficiency of phosphorus fertilizer.

Therefore, when planning the fertilizer manufacturing process and using plant ash as organic raw material, the fertilizer plant should pay attention to the proportion of raw materials.

1. Soil application: since the ash is alkaline, cohesive soil, acidic or neutral soil should be used. Soil application can be used as base fertilizer, seed fertilizer and topdressing, as well as seedling raising and seedling covering (seed covering fertilizer).

When used as base fertilizer and seed fertilizer, the amount of fertilizer should not be too large, and should be isolated from seeds to prevent seed burning. Generally, 50-100kg per mu is appropriate.

It is suitable for centralized soil application, strip application or hole application, with a depth of 8-10cm, and covered with soil after construction. Mix the wet soil 2-3 times or spray a little water before application.

2. Topdressing outside the root: more than 90% of the potassium contained in plant ash is soluble in water, which is a quick acting potassium fertilizer. According to this characteristic, plant ash can be used as extraroot topdressing, that is, 1% concentration of plant ash extract can be used for foliar spraying.

3. Priority crops: plant ash is suitable for various crops, especially potassium free or potassium free and chlorine free crops, such as potato, sweet potato, tobacco, grape, sunflower, sugar beet, etc.

Plant ash can be used for potato, not only for soil application, but also for potato wounds. In this way, it can be used as seed fertilizer to prevent wound infection and decay.

More types of fertilizer machines for organic fertilizer production, go to https://compostturnermachine.com/

Conventional organic fertilizer production machine configurations

1. Compost Dumper: industrial fermentation treatment of organic solids such as livestock manure, domestic waste, sludge and crop straw. The equipment integrates the uniformity of fermentation materials. Therefore, the front of the fermentation tank can be freely put in or taken out, and waste such as feces can be retained for a long time.

2. The mixer has fast mixing speed and good uniformity. It can mix 30% liquid and add viscous materials. There are two rotors working in opposite directions. Because the blade has multiple special angles, it can mix quickly and efficiently regardless of the shape, size and density of the material. The lower door opening speed is fast and the residue is less.

3. Wet material crusher is a professional crushing equipment for crushing high humidity and multi fiber materials. The high-speed rotating blade has the advantages of good particle size, high efficiency and high energy. Semi wet material crusher is mostly used for the production and processing of organic fertilizer. The crushing effect of chicken manure, sodium humate and other raw materials is very good.

4. Organic fertilizer granulator is a molding machine that can make materials into specific shapes. It is widely used in the production of organic fertilizer, bio organic fertilizer and other fields.

5. When the rotary cooler cools to a certain temperature, it can reduce the moisture content, reduce the labor intensity and improve the output.

6. The rotary dryer is mainly composed of rotating body, lifting plate, transmission device, support device and sealing ring, with diameter of: Φ 1000- Φ 4000, the length depends on the drying requirements. Collect the dried product from the bottom of the bottom.

7. Drum screen adopts combined screen, which is convenient for maintenance and replacement. The machine has the advantages of simple structure, convenient operation and stable operation. Drum screening machine is mainly used for the separation of finished products and returned materials. It can also realize the classification of finished products and uniform sorting of finished products.

8. The coating machine is composed of screw conveyor, mixing tank, oil pump and main engine, which can effectively prevent the caking of compound fertilizer. The main body is made of polypropylene lining or acid resistant stainless steel.

9. The packaging machine is mainly composed of feeding mechanism (gate), weighing bucket, bag clamping mechanism, frame, air inlet, pneumatic system, sensor, control box, conveying and sewing mechanism.

More detailed info, go to https://compostturnermachine.com/complete-granule-production-line-solutions/

Organic fertilizer products yileds improvement

In a complete organic fertilizer manufacturing process for manure fertilizer production, fermentation, granulation and crushing are three key steps. Therefore, fermentation stacker, organic fertilizer granulator and organic fertilizer crusher play an important role in all organic fertilizer equipment. Let’s discuss the problems that may be encountered in the production process of these two key links.

How to improve the product output and output, the key lies in the organic fertilizer granulator.

1、 According to the moisture, fineness and cohesiveness of raw materials.

1. Moisture

Powder raw materials form spherical particles through the attachment of water. Therefore, controlling water and making water uniform have become the key factors to improve yield. The lower the moisture content, the lower the granulation rate, the higher the moisture content, the more large particles, the uneven moisture, the smaller the particle size, and the lower the yield.

2. Material fineness

It is needless to say that the material fiber has natural coarse granulation effect, rough and brittle appearance and poor formability. The higher the fineness, the better the formability and the smoother the particles.

3. Is the material sticky

In particular, organic fertilizer granulation, general raw animal manure (chicken manure, pig manure, cow manure, sheep manure, pigeon manure, etc.), straw (corn straw, straw, leaves, etc.), fungus residue, sugar residue, drug residue, monosodium glutamate residue, etc. The viscosity of general materials is poor, so some viscous fillers such as bentonite need to be added.

2、 Fertilizer granulator is selected for organic fertilizer production line.

For example, the production of granules can choose disc granulator, new organic fertilizer granulator and drum granulator.

If columnar is produced, ring mold granulator and columnar extruder are selected.

For irregular and flat ball type, select the appropriate drum extrusion granulator (depending on the die).

All kinds of granulation equipment have their own advantages and disadvantages. Different equipment shall be selected according to raw materials, investment cost (drying or not) and the needs of farmers.

3、 Equipment operation

1. For example, the disc granulator can pass the inclination of the disc. The more flat the disc is, the larger the particles are, the steeper the disc is, and the smaller the particles are.

2. According to the control of material moisture, the larger the moisture, the larger the particles, the smaller the moisture, and the smaller the particles.

3. According to the speed, the higher the speed, the smaller the particles, and the lower the speed, the larger the particles.

In general, the uneven particles of organic fertilizer are mostly caused by the uneven mixing of materials and the thickness of material fiber.

Latest Technology for Bio Fertilizer Production

The technical content of biological fertilizer project is high. In addition to the biological agents that promote the maturation and decomposition of organic matter in the maturation process, in order to achieve targeted maturation and deodorization, microbial products with specific functions need to be added to enhance the effect of the products.

At present, bio organic fertilizer is included in the category of microbial fertilizer in China, and more strict management measures are implemented than organic fertilizer to promote the healthy development of organic fertilizer.

1. The production process of bio organic fertilizer production enterprises registered with the Ministry of agriculture is basically engaged in the production of microbial fertilizer. In the process of fermentation production, tank stacked fermentation is mostly used, and there are other fermentation methods, such as flat stacked fermentation and fermentor fermentation.

In the process of fermentation and maturation, the adjustment of material moisture, carbon nitrogen ratio and temperature and the use of curing agent are the production process. The key is that the application of fungicide directly affects the fermentation cycle and the maturity of materials. The ripening material basically achieves the harmlessness of the product and is also conducive to the survival of the functional bacteria added in the post-treatment process.

2. In terms of post-treatment of fermentation materials, most enterprises add functional bacteria for compound molding. The dosage form of the product is mainly powder, and some are granulated by rotary drum fertilizer granulator or roller granulator. Granular products prevail over powdered products. The disadvantages of poor appearance and low grade not only improve the commerciality of the product, but also increase the production cost of the enterprise, which has a certain impact on the survival of effective bacteria.

3. The utilization of strains and microbial strains is the core of bio organic fertilizer products. In the production process, there are generally two links related to the utilization of microorganisms:

First, add decomposition bactericide to promote material decomposition and decompose and deodorize in the decomposition process. It is mainly composed of complex strains.

Common strains include photosynthetic bacteria, lactic acid bacteria, yeasts, actinomycetes, Penicillium, wood fungi, etc; Second, the functional bacteria added after material decomposition, generally nitrogen fixing bacteria, phosphorus solubilizing bacteria, silicate bacteria, lactic acid bacteria, Pseudomonas, actinomycetes, etc., play a specific role as fertilizer in the product.

Therefore, the selection and use of microbial strains for the production of bio organic fertilizer is a core technology. Only by mastering this key technology can we accelerate the decomposition and maturity of materials, Ensure the application effect of the product.

More detailed info, go to https://organicfertilizerplants.com/bio-organic-fertilizer-production/

Flat Die Granulator for Organic Fertilizer Production

The production process of organic fertilizer is mainly to granulate and dry the organic waste with water content of about 30% decomposed by fermentation, prepare round organic fertilizer by granulation and drying, add functional bacteria to produce biological organic fertilizer, and add nitrogen, phosphorus and potassium (total nutrient content is less than 15%) to produce organic and inorganic fertilizer.

After screening the fermented organic waste, the binder raw materials and other components to be compatible are measured and proportioned in proportion, and quickly mixed by the bucket elevator into the fertilizer mixer for rapid mixing.

The material slides out of the mixing bin and is evenly and continuously fed into the flat die extrusion fertilizer granulator by the disc feeder to form columnar particles; Cylindrical particles (equal in diameter and length) are polished by a circular particle polishing machine. The spherical particles are sent to the drying, cooling and screening machine by belt conveyor.

The particles are dried at low temperature and large air volume in front of the drying cooling screening machine, and then enter the cooling section for air blowing. The cold and completely cooled materials enter the screen installed at the end of the cylinder, screen out the powder and large particles, and return to the mixed granulation system; The finished product particles are transported to the finished product silo by the elevator, measured, packaged and warehoused.

Process characteristics

(1) The new technology of flat die extrusion granulation and rounding and finishing can produce “spherical” pure organic fertilizer, organic-inorganic fertilizer and biological organic fertilizer. The process is short, the operation cost is low, the organic fertilizer particles are uniform and round, the surface is smooth, the compressive strength is high, the fluidity is good, the microbial survival rate is > 90%, the granulation rate is 85-95%, and the particle size is 3.5-4mm.

(2) The new process of flat die extrusion granulation and rounding finishing has strong adaptability to raw materials and can solve the key technical problems that are difficult to be solved by traditional granulation processes such as disc or drum:

1. The fermented organic matter can be directly used for granulation without pre drying and crushing.

2. The amount of organic materials can be increased to more than 95%.

More detailed info on fertilizer production machines, go to https://fertilizerplantequiment.com/

Granulation Equipment for Fertilizer Production Maintenance

Organic fertilizer is an indispensable raw material in today’s agricultural production. Organic fertilizer granulator converts materials into organic fertilizer and then processed into particles, which can help customers better package and use. Let’s talk about the steps and equipment needed in the production process of organic fertilizer.

Steps and equipment required for making organic fertilizer:

1. Ground strip stacker, crawler tipper, or material fermentation tank, trough thrower

2. Evenly sprinkle microbial agent, turn over the pile for fermentation, heat, smell, decompose and kill bacteria

3. Ferment for 15-20 days. According to different temperatures and times, use the dumper to improve the fermentation speed.

4. Complete fermentation, decomposition and out of the tank (ground type, direct stacking with forklift)

5. Coarse and fine screening with screening machine (the screened powdery fertilizer can be sold directly)

6. The screened large pieces are crushed by the crusher and returned to the screening machine.

7. Mix the required trace elements with a premixer,

8. Granulate with fertilizer granulator.

9. Enter the dryer and cooler for drying and cooling.

10. Automatic packaging machine for sale

Maintenance method of organic fertilizer granulator:

1. Start preheating and replace grease.

2. Replace the gear oil.

3. Reasonable maintenance, full and reasonable maintenance is very necessary.

4. Replacement of vulnerable parts. Vulnerable parts are the main working parts of the new organic fertilizer granulator.

5. Humanized production. The humanized culture and humanized operation of the equipment is a warm measure to ensure the normal operation of the machine.

Introduce the steps and equipment required for making organic fertilizer and the maintenance knowledge of the equipment. Hope to help you.

How to set up a organic fertilizer production plant?

Conditions for constructing small organic fertilizer production line

What conditions do we need to build a small organic fertilizer production line? Small organic fertilizer production line can be a powder organic fertilizer production line, or can be a granular organic fertilizer production line.

The production lines of organic fertilizer with an annual output of less than 20000 tons are small organic fertilizer production lines. According to the planning of most customers, the small organic fertilizer production line has 5000 tons, 10000 tons, 15000 tons and 20000 tons.

Because the production line of powdery organic fertilizer is the component of the production line of granular organic fertilizer, we will use the granular organic fertilizer production line to elaborate the technology of small organic fertilizer production line today. The technology of fertilizer production line will be clear.

Process flow of granular organic fertilizer production line:

(1) Crushing process;

(2) Fermentation process;

(3) Mixing process;

(4) Granulation process;

(5) Drying process;

(6) Screening process;

(7) Coating process;

(8) Packaging process.

The process flow of powdery organic fertilizer includes the following contents:

(1) Crushing process;

(2) Fermentation process;

(8) Powder packaging process.

So, what conditions do we need to build a small organic fertilizer production line?

(1) The construction of small-scale organic fertilizer production line meets the requirements of environmental protection policy. Environmental protection is not only the desire of the people, but also the policy demand for environmental protection for the development of agriculture and animal husbandry;

(2) Raw material source, radius of raw material source, determine your plant location, site investment, transportation investment, etc;

(3) The types of raw materials, the specific equipment types used in each stage of the process, and the investment price of the equipment are affected;

(4) The production scale, the production capacity of small organic fertilizer production line from 3000 tons to 20000 tons determines the equipment capacity requirements, thus affecting the price;

(5) The recycling of resources mainly depends on a variety of agricultural pollution waste recycling methods, such as fuel and electricity raw materials, and biogas residue is used as organic fertilizer raw material;

(6) Other small organic fertilizer production line technology, can be used as feed.

(7) Site: the size of production site and investment of site scale shall be determined according to the planned production scale.

Detailed Machine Configurations on Organic Fertilizer Production at Small Scale

As the name implies, the small-scale organic fertilizer equipment production line is a complete set of small-scale organic fertilizer production equipment. The included equipment is also semi-automatic. The following are the equipment included in the production line of small organic fertilizer equipment.

1. The pre fermentation and turning equipment mainly plays the role of composting and material turning, and is more suitable for microbial fermentation to store manure into fertilizer. The technology requires that the viscous storage manure can be effectively mixed with microbial preparation and straw powder. It can not only ferment fast, but also prevent the production of harmful odor gas in fermentation process, which meets the environmental protection requirements.

2. The special pulverizer for organic fertilizer is mainly used for better crushing and fermentation materials, which lays a solid foundation for the next scheme provider. When choosing organic fertilizer pulverizer, we must choose the suitable ones for their own use, and do not blindly. If selected, otherwise, the crushing effect will not be reached, but the normal operation of the next process will be affected.

3. Organic fertilizer mixer is used for mixing formula fertilizer, adding various substances, mixing evenly, and carrying out the next process.

4. The granulator of organic fertilizer mainly plays a role in granulation. The mixed material is uniformly fed into the granulator by conveyor for deep granulation. It can be made into various sizes and shapes according to the local market. There are many kinds of granulator styles and models, and the appropriate granulator can be selected according to the production and requirements of customers.

5. The dryer mainly acts as evaporation material moisture. Because of the large water content in the granulation process of fertilizer granulator, it can not meet the national requirements. The granulation can not be packed immediately, and the moisture should be dried by drying equipment. Evaporation to the state of national standards for the next process.

6. cooling machine. Because the temperature of the dried material is high, it can not be packed immediately, and the woven bag is easy to be burned. The temperature of material needs to be reduced to constant temperature quickly through cooler to carry out the next process.

7. The screen separator mainly plays a role of grading. Because of the granulator granulation rate, the difference of dryer and cooling opportunity, and the particle damage, it is necessary to distinguish the finished particles from the inferior products. After the next procedure, the defective products will be re comminuted and the granulation cycle work will be carried out.

8. Automatic packaging machine mainly plays the role of finished product particles, automatic.

Organic Fertilizer Production Technology and Machine Configurations

I said that we have a professional organic fertilizer production line to help us make organic fertilizer.

The basic process includes fermentation process, complex process and granulation process.The most important part is the granulation process.

Granulation process section

(1) Crusher (fertilizer crusher)

The materials were crushed and fermented for 1 day, then dried, crushed and screened for fermented organic materials.

For raw materials pre-treatment, go to https://fertilizerplantequiment.com/vertical-fertilizer-crusher/

(2) Compounds and mixtures (fertilizer mixers)

In the process of making a series of special fertilizers, inorganic nutrients and minerals should be added according to different soil conditions and different crops. These minerals are concentrated in organic matter and trace elements, so that the fertilizer contains various nutrients needed for plant growth, such as nitrogen, Phosphorus, potassium, sodium, manganese, zinc, copper, etc.

According to the formula, nitrogen, phosphorus, potassium and fermentation material are mixed by computer and transferred to granulator for granulation. We mix organic and inorganic materials according to different series of products, and mix them well in blender. Assume that the proportion of organic materials is 12%, about 12 tons.

In this process, composting turner is the most important machines. How choose a quality compost turner? Go to https://fertilizerplantequiment.com/compost-windrow-turner-for-sale/

(3) Pelletizing (fertilizer granulator)

The production process should not be exposed to high temperature and other characteristics due to the poor formation conditions of bio fertilizer mainly composed of organic matter and cellulose and the viable bacterial population with the function of making fertilizer.

Disc granulation and drum granulation are not suitable for building materials, because these two technologies require fine grinding of raw materials, high moisture content of granulation, and generally the moisture content is about 30%, so the load is relatively large. There are different types of fertilizer granulators for your fertilizer granulation process.

For drying, the loss of effective bacteria is great, and the pelleting rate is low (about 60% – 70%), the dust is heavy, and the operating environment in the production process is poor.

Therefore, through the extrusion environment, the requirements of raw material crushing are low, the molding rate is high (more than 95%), the water content of formed particles is low, the drying load is low, the environment is dry, and the production of organic biological functions should be better. Can reduce the loss of effective bacteria, less dust and good working environment.

70 tons of organic fertilizer raw materials, using organic fertilizer special granulator. After granulation, the material is sent to the dryer by belt conveyor for drying. The particle size is 3.0-4.0 mm, and the granulation rate is more than 70%.

The recommended pelletizer is a new type of pelletizer for organic fertilizer.

(4) Drying (fertilizer dryer)

In the production process of biological fertilizer, not only does the moisture content of granules generally exceed the index after molding and need low-temperature drying, but also the moisture content of organic matter after fermentation is about 30% – 40%, and the granule after granulation is generally between 15% – 20%, which needs drying treatment, because the moisture content of fertilizer quality index is less than 14%.

The drying stage is an essential and important process in the production of biological fertilizer, which directly affects the yield, quality and energy consumption. It is very important to choose the type and specification of dryer and control the process conditions.

In order to avoid the death of effective living bacteria due to the high temperature in the drying process, the drying temperature of materials should not be higher than 60 ℃ (usually about 50 ℃). Therefore, the temperature of hot air in contact with materials should be different.

For the moisture content of different materials, generally not more than 130 ℃, it is better to control the hot air temperature by stages, which can not only improve the thermal efficiency, but also effectively avoid the death of living bacteria.

According to these characteristics, the belt dryer is suitable, because it is suitable for low temperature and low humidity drying, and it can control the temperature of hot air in sections to ensure that the material temperature is not higher than the drying temperature, and maintain the highest temperature in the whole process.

The tail of the dryer can also add natural air cooling part, and cool the material immediately after drying, It can be used many times.

It is very suitable for granular biological fertilizer, with drying permeability, stable and uniform drying of materials, no damage to particles, adjustable residence time and feeding speed to achieve the best drying effect, because most of the thermal circulating air has high thermal efficiency, and the heat source can be used.

There is a secondary granulation area in front of the steam dryer provided by the biogas boiler, The material can be granulated there. Then, the material is lifted up through the plate to be completely dried. The exhaust machine exhausts the humid hot air through the pipe at the end of the dryer, and the air enters the precipitation chamber for precipitation.

After precipitation, the tail gas is removed by the washing tower, and the ejected water is pumped out for recycling. After secondary dust removal, the waste gas is discharged into the atmosphere through the chimney.

(5) Cooling (drum cooler)

The dry material is cooled by belt conveyor and sent to cooler. The cooling process mainly includes using fan to send natural air to cooler through pipe to cool the material.

The wind direction in the cooler is counter current. The waste gas pumped into the settling chamber by fans and pipes is treated and discharged into the atmosphere as dry waste gas

After cooling, the material is screened, the crushed large particle material and the screened powder are transported to the granulator through the return belt for granulation, and the final product is packaged in the automatic packaging system.

More details go to https://fertilizerplantequiment.com/organic-fertilizer-manufacturing-plant/

How to kill pests in organic fertilizer production process from animal manure?

The main raw material for organic fertilizer production is animal manure. There are many untreated or improperly treated pests in animal manure, such as treated, worms and so on. These pests breed and cause damage to vegetables, grains, fruits and so on.

Crops are good organic fertilizers. But we often find that when using crops, fertilizer sometimes leads to a large number of soil diseases and insect pests, And it increases year by year. I have been doing tests for several years and achieved good results. Now I have become a common element in fertilizer treatment to be faithful to agriculture.

1. Flatten poultry feces, dry in the sun, mash fine powder, and mix 1 kg of thiophene per cubic meter. After the round table is piled up, mix evenly and smear with flat mud for 15-20 days.

2. Mix fresh cow dung and sheep ash with 30% ash, then spread to 10 cm thick and spray 1 kg liquid per square meter. Liquid preparation: water 1605, carbendazim ratio 100:0.2:0.3.

Referer url, go to https://organicfertilizermachines.com/

3. When exposed to the sun, half human manure should be piled into a truncated cone of 50cm in the shape of a high platform, with flat mud paste, and several drugs on the top of the cork should be used to penetrate the hole, with the depth of 40cm, and then filled with liquid.

Liquid preparation: the ratio of water to trichlorfon was 100:0.5.

The first step of our organic fertilizer production line is fermentation composting, which is a process of killing pests. You can learn about the fermentation mode and site construction method of organic fertilizer. We have several fermentation composting turnover machines that can be selected according to our actual needs.

4 Characteristics of organic fertilizer production line

1. Semi wet material crusher is adopted, which has strong adaptability to

moisture content.

2. The polishing machine can make spherical particles with uniform size, smooth surface and high strength. Suitable for connection with various granulators.

3. Use belt conveyor and other supporting equipment to connect the whole production line.

4. Compact structure, stable performance, easy operation and maintenance.

5. According to your actual needs, the equipment is optional.

For the construction of customers, we can provide free construction drawings. Welcome to contact us!

More detailes info, type here

3 key steps to make organic fertilizer products

The three main processes of organic fertilizer production line include organic fertilizer fermentation, fertilizer granulation and fertilizer drying and cooling.

1. First, the organic fertilizer production line ferments and decomposes livestock manure and other raw materials. The whole process of fermentation can kill the internal harmful bacteria, and killing bacteria is also an important step in the whole process of organic fertilizer production.

Secondly, it is necessary to use semi wet material crusher equipment of organic fertilizer to crush livestock manure and raw materials. Raw material matching is one of the important processes of organic fertilizer production line.

The main purpose is to add appropriate amount of auxiliary materials according to the formula proportion to improve the quality of fertilizer. Mechanical granulation should be carried out after the raw materials are evenly mixed, which is one aspect of the whole organic fertilizer production line process.

The complete organic fertilizer production line includes three processes

2. It is especially suitable for high viscosity materials. The material of fertilizer granulator should meet the production requirements of pressure, temperature and catalyst resistance, and keep the product clean. Due to the different materials of fertilizer granulator, the production process and structure of fertilizer granulator will be different, so it can be divided into steel, lining equipment, etc.

The complete organic fertilizer production line includes three processes

3. High temperature energy can be obtained after the raw materials are dried, and the next step is to cool them at low temperature. Since water cannot be used for cooling, it is necessary to separate the contact between material and water through cooler. The screening machine will screen unqualified organic fertilizer particles. The screening equipment has the advantages of high efficiency and easy operation. More details, go to https://organicfertilizerplants.com/organic-fertilizer-production-process/

What to do before organic fertilizer production?

Organic fertilizer production line is the production line of organic fertilizer particles and organic fertilizer powder. As we all know, if you want to granulate organic fertilizer, you must first make it into powder, and then granulation, so the powder production line is an important part of the particle production line.

Now, I will introduce the process of the organic fertilizer production line in detail together with the granular organic fertilizer production line. According to the process layout, the process flow of granular organic fertilizer production line is: Fermentation – crushing – mixing – granulation – drying – Screening – Coating – packaging. The technological process of powdered organic fertilizer includes the above four processes (fermentation, crushing, screening and packaging).

The preparations for the construction of the organic fertilizer processing plant are as follows:

1) The construction of organic fertilizer production line should meet the requirements of environmental protection policy. Environmental protection is not only the desire of the people, but also the policy requirement of the development of agriculture and animal husbandry for environmental protection.

2) The source of raw materials and its surrounding radius determine the location of the factory, site investment, transportation investment, etc.

3) The type of raw materials determines the detailed equipment used in each process stage and affects the investment price of the equipment.

4) The production scale of an organic fertilizer production line is from 3000 tons to 250000 tons per year, which determines the capacity demand of the equipment and affects the price.

5) The recovery of resources mainly depends on the recovery of agricultural non-point source wastes, such as fuel and electricity raw materials and biogas residue as organic fertilizer raw materials.

6) The organic fertilizer production line can be used as feed for other purposes.

7) Construction site: the production site scale and investment scale must be determined according to the planned production scale.

Technology Employed in Organic Compost Pellet Production

China has a vast territory and rich raw material resources for organic compost equipment. It is understood that the final urine excreted by a pig in a year can be combined with bedding material to produce 2000-2500kg of high-quality organic compost, which is enough for one mu of land to use chemical compost throughout the year. The content of components is more than 6%, and the content of organic matter is more than 35%, which is higher than the national standard.

In the organic compost production line, we can use the drum granulator, or we can equip the drum granulator in the organic compost production line to complete the production process of NPK compost granulator. The granulation method completes the production process. This is different from rolling compost granulator, which usually uses dry granulation method to produce compost granulator.

In the bio organic compost production line, different types and series of compost equipment should be equipped to complete the production process. These machines play different roles in the compost manufacturing process.

Equipped with fermentation composting machine for a certain period of fermentation of raw materials, and then equipped with compost mixer, the relative type of compost crusher processing raw materials.

In the production of compost granulator, the compost granulator should be designed and equipped on the production line to manufacture bio organic compost granulator. In the biological compost production line, we can use the flat mold granulator to manufacture the biological organic compost granulator, and we can also use the drum granulator. Complete the granulation process on the production line.

7 ways to make organic fertilizer

Organic fertilizer granulation production line is to use chicken, sheep, pig manure as the main raw materials, add a certain amount of nitrogen fertilizer, phosphorus fertilizer, potassium fertilizer, magnesium sulfate, ferrous sulfate and other substances, with rice bran, yeast fermentation, soybean meal and sugar in a certain period of time as a kind of biological bacteria, in the role of sulfuric acid, mixed fermentation equipment to make biological fertilizer.

Process flow of complete set of equipment for biological fertilizer production:

1. Fermentation: collect poultry feces and urine, mix with hay and rotten silage to make compost, and then ferment. In the fermentation process, the cow dung is completely fermented by the stacker, which can only be achieved by stacking in time and evenly.

2. Raw material comminution and mixing: use the raw material bin to mix composting materials, N, P, K and other inorganic fertilizers, other additives and other raw materials, and pass through the pulverizer and horizontal mixer in proportion. Mix.

3. Pelletizing: use a new type of organic fertilizer drum pelletizer to pelletize materials.

4. Screening and material return system: the granular materials output from the granulation system have different particle sizes and need to be screened and classified.

5. Drying: use the organic fertilizer dryer to further remove the moisture in the sieved particles, so as to meet the standard requirements of the moisture content of organic fertilizer.

6. Cooling: cooler is used to cool granular materials, which is helpful for the storage and quality of particles.

7. Packaging: the granular materials cooled by the organic fertilizer equipment are transported to the finished product warehouse by bucket elevator. Granular materials can be weighed quantitatively and packed by automatic packing scale

A complete set of organic fertilizer granulation production line process: raw material selection, drying and sterilization, fermentation, crushing, stirring, granulation, drying, cooling, coating, screening, metering and sealing, product storage.

The complete set of fertilizer production equipment is mainly composed of fermentation system, drying system, deodorization and dust removal system, crushing system, batching system, mixing system, granulation system and finished product packaging system. The fermentation system includes: feed conveying, which is composed of machine, biological deodorant, mixer, special car polishing machine, oxygen supply system and automatic control system.

Quality Organic Fertilizer Production Solutions

The fertilizer machine manufacturer of the organic fertilizer production line will tell you the reason for the caking of organic fertilizer. The sx manufacturer of the organic fertilizer production line said in the last article that in fact, the premise of prevention is to find out the cause of caking. Everyont also knows that caking is not conducive to the use of organic fertilizer, and has a certain impact on the production and use of organic fertilizer. Want to answer why pig manure organic fertilizer production line caking.

We usually use the materials for fertilizer production, such as ammonium salt, phosphate, trace element salt, potassium salt, etc., most of which contain crystal water and are easy to absorb water and caking, such as ammonium sulfate, which is easy to caking in use. When urea meets with trace element salt, it is easy to agglomerate when releasing water, mainly because urea replaces trace element salt. The crystal water becomes mushy and agglomerates.

In the process of chemical fertilizer production, chemical fertilizer production is generally non closed. In the production process, the higher the air humidity is, the easier the fertilizer is to absorb water and caking. If the weather is dry or the raw materials are dry, the fertilizer will not agglomerate easily.

Organic fertilizer production line

The higher the room temperature of extruder granulator, the easier to dissolve. Generally speaking, raw materials will dissolve in their own crystal water, leading to caking. The higher the temperature of nitrogen, the water will evaporate and not caking easily. The temperature is usually higher than 50 ℃. We usually need heating to reach this temperature.

The greater the pressure applied on the fertilizer, the easier the contact between the crystals and the easier the agglomeration; the smaller the pressure applied, the less the agglomeration.

The longer the fertilizer is placed, the easier it is to agglomerate. The shorter the time, the less likely it is to agglomerate.

Only when the production line of organic fertilizer does not ignore the problem of caking, can we find out the reason of caking. Serious caking may even affect the use efficiency of organic fertilizer.

How organic fertilizer is made?

The organic fertilizer production line from sx organic machines is designed for the production of organic fertilizer granulator. In the process of organic fertilizer production, different types of fertilizer equipment are equipped to complete the production process. Here, we introduce the characteristics of organic fertilizer.

In the process of organic fertilizer production, organic fertilizer can be divided into powder organic fertilizer and granular organic fertilizer.

Among them, the technology of powdery organic fertilizer is relatively simple

1. Check the ingredients of your raw materials (such as plant ash, furfural residue, humic acid, etc.) to understand the accurate nutritional composition and proportion of each raw material, which plays an important role in the production of organic fertilizer;

2. The general production process of organic fertilizer requires the content of nitrogen, phosphorus and organic fertilizer granulator or disc granulator or roller granulator; the production process of organic fertilizer requires the content of nitrogen, phosphorus and potassium to be more than 4% and the content of organic matter to be more than 30%. So organic fertilizer can be mixed, crushed and packaged.

In addition, fertilizer equipment such as drum granulator, organic fertilizer granulator, disc granulator or roller granulator is required for organic fertilizer granules. The production of organic fertilizer requires the same raw materials as powder fertilizer, but after adding binder (bentonite or green palygorskite), the final particles need to be dried by rotary dryer.

Organic fertilizer production line

There is also an organic fertilizer with livestock manure, domestic waste and plant straw as the main raw materials.

The production process of the organic fertilizer is as follows: raw material drying, crushing, fermentation, mixing (mixed with chemical fertilizer). And other organic or inorganic substances, so that nitrogen, phosphorus, potassium content into particles (or not into particles, powder) and then packaging.

If the raw material is humic acid or peat, the organic fertilizer will not be fermented in the production process, and there is no need for fermentation. Other steps are the same as above.

As a professional fertilizer machinery manufacturer, we mainly produce all kinds of fertilizer equipment to complete the fertilizer production process. Our main products include not only fertilizer granulators, but also different types of fertilizer production lines.

Bio Fertilizer Production Easy Tips

The production of organic fertilizer or bio fertilizer granulating machine can use fertilizer manufacturing technology, and a complete fertilizer production line is designed to produce pelletizer, and different types of fertilizer machines are equipped in the process of fertilizer manufacturing.

The so-called bio organic fertilizer production line is actually the ordinary organic fertilizer production line. The main reason for the difference between biology and common organisms is that in the process of production, the production line of bio organic fertilizer increases the link of adding microbial agents, which leads to the final production of organic fertilizer and bio organic fertilizer.

The production line is organic fertilizer fermentation. In order to better explain the difference between the two production lines, let us first understand the difference between the production process of organic fertilizer and the production process of biological organic fertilizer.

Flow flow of organic fertilizer production line:

The basic process of the production line is as follows: the use of fermentation compost dumper to collect raw materials, and then stack and ferment raw materials can save more time. Next, the raw materials are crushed by the fertilizer pulverizer, and then screened by the screening machine. Raw material, then premixed. Next, the granulator is made by a fertilizer granulator. After granulation, the granulator is treated with a dryer and a cooling machine. Finally, the screening machine is used to screen and pack the high quality fertilizer.

Process flow of bio fertilizer production line:

In the process of bio organic fertilizer production line, raw materials shall be collected first, then bio fermentation with organic fertilizer starter shall be used to complete fermentation of semi-finished organic fertilizer products, then premixes shall be crushed and then pelletized, and then the granulator shall be dried and cooled by the fertilizer dryer dryer and cooling machine. Finally, the second screen and the pelletizer are packed.

From the above two kinds of organic fertilizer production, we can see that fermentation is the first and most important link of organic fertilizer production, because the final use effect of the organic fertilizer is in this link.

As a professional fertilizer machinery manufacturer for organic fertilizer equipment and inorganic fertilizer equipment, we not only designed the organic fertilizer production line, but also designed the biological fertilizer production line. These equipment will also be used in the bio fertilizer production line. Production of bio organic fertilizer granulating machine.

Leading Technology in Organic Fertilizer Production

At present, the growth of agricultural production generally depends on chemical fertilizer. On the one hand, it will cause environmental pollution. In fact, the non-point source pollution in rural areas is very serious, which has become a problem. On the other hand, it will affect the quality of agricultural products.

Therefore, people gradually realize that when using chemical fertilizer, we must increase the proportion of organic fertilizer, especially for vegetables, fruits, tobacco and other economic crops. The use of biological fertilizer can not only increase yield, but also improve quality and protect crops. Ecological environment, extensive use of municipal waste, sludge, livestock manure, orange and other waste. How to turn these organic materials into fertilizers, go to https://organicfertilizermachines.com/

The new technology of biological fertilizer production technology is used to produce biological fertilizer, which makes “grain fertilizer grain” form a virtuous circle chain. Therefore, biological fertilizer has become a new fertilizer and new fertilizer industry for the development of ecological home industry.

Organic fertilizer has the following characteristics:

1, rich in nutrients, high content, containing all kinds of nutrients needed for crop growth.

2. The effect of chemical fertilizer lasts for a long time, with both pre effect and post effect, which can fully meet the needs of various nutrients for crops in the whole growth period, but not in the late growth period. Interested in organic chemical fertilizer production? Go here.

3. It is simple and convenient to use. It can be used as base fertilizer at one time. The method is simple, labor-saving and time-saving.

4. The cost is low, and the price of similar goods is the lowest.

5. High efficiency, input ratio is more than 1:10-30.

6. It is widely used in all kinds of soil and crops, including all kinds of greenhouse vegetables, fruit trees, cash crops, food crops, medicinal materials, flowers, lawns, seeds, etc.

Conditions for plant construction:

Reliability of raw material supply. The main raw material of this product is animal manure. Auxiliary materials include: peat, sawdust, straw, soybean cake, corn flour and other wastes. No more than 70 tons of raw material should be used per day.

Process of organic fertilizer production line:

The main ingredients include rice straw, pig manure, charcoal, etc.

The production process of organic fertilizer mainly includes: inoculation and fermentation of organic matter, main fermentation, crushing, ingredient mixing, drying, grading, cooling, screening, metering and packaging, etc.