Fertilizer packaging machine can be divided into automatic packaging machine and semi-automatic packaging machine from the degree of automation. The former does not require human involvement in the entire packaging process, while the latter requires some auxiliary cooperation. Of course, the price of the two fertilizer manufacturing equipment is different, and customers can choose according to their own needs.

Semi-automatic packaging machine only needs to hang the bag manually. The weighing method of the equipment can be selected according to the actual needs of the upper weighing and lower weighing. The material falls due to gravity. When the weight is close to the target weight, the unique two-stage control valve ensures accurate weighing of the material.

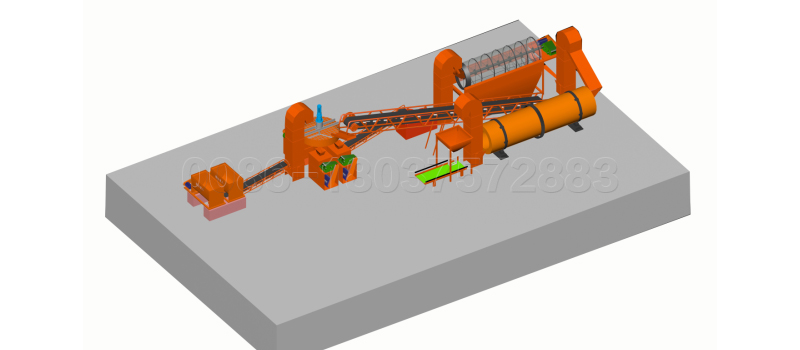

Compared with manual operation, the advantages of organic fertilizer automatic packaging machine are very obvious. In the entire process of drum granulation, packaging can be completed with a simple operation. In the past, the equipment of the ton bag industry was simple and rough, and the packaging mainly relied on forklifts and manual filling.

This way not only requires a lot of human resources, but also highly polluting materials are easy to cause harm to the human body, especially the work efficiency is much lower than that of fertilizer packaging machines.

With the continuous development and improvement of packaging machines, a variety of products such as single bucket packaging scales and double bucket packaging scales have been derived for users to choose. When purchasing, users can freely choose according to their own materials and packaging needs.

More detailed info, welcome go to https://www.fertilizermachinesale.com/