With the popularization of organic fertilizer, the use of organic fertilizer production equipment is also greatly increased, which makes the demand of organic fertilizer equipment increase year by year.

Therefore, the standard operation of organic fertilizer equipment has become the focus of attention. The following is a brief introduction to the matters needing attention when the organic fertilizer manufacturing process is newly built and the project is put into use.

1. Before the start-up of organic fertilizer production equipment

Since all parts of the new equipment are not yet in operation, it is necessary to heat up the equipment for the first time, which usually takes 40-50 minutes. For a specific operation, first raise the temperature, pull the motor V-belt by hand until it is released, and then continuously pull the motor 8-10 times according to the normal operation option. Then keep heating for about 10 minutes.

2. Temperature control after start-up

Before starting the machine, we have made a preliminary temperature adjustment on the equipment. The material treatment of organic fertilizer equipment in the production process is determined by the characteristics of the material itself. Therefore, heating should be continued after start-up, because normal production requires continuous heat supplement; different temperatures are adjusted according to different properties of plastics.

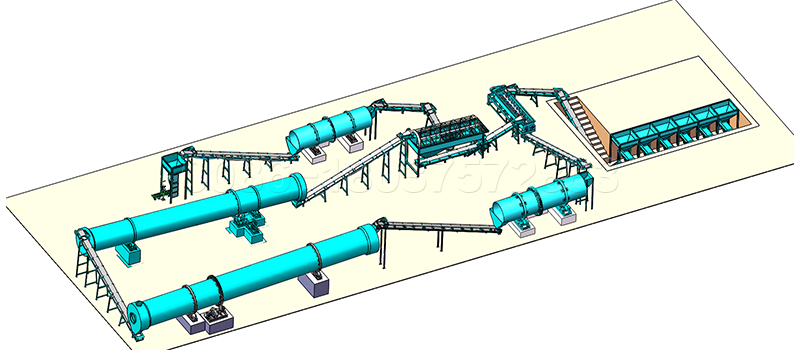

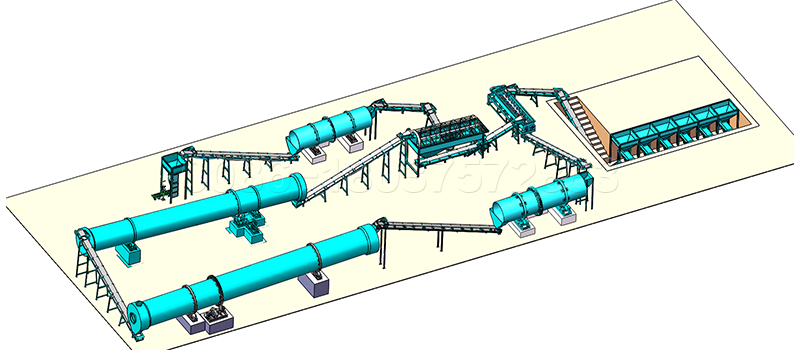

Manufacturing technology of organic fertilizer

3. When the fertilizer manufacturing process works normally

During normal operation, the temperature of the drum granulator should be stable and should not be high or low. The temperature should be about 200 ° C near the nozzle until the machine head. At this temperature, most materials can be treated well. For the double roller granulator, granulation can be carried out at normal temperature, and the moisture content of materials should be paid attention to during the granulation process.

4. Close the organic fertilizer manufacturing process

First of all, cut off the power supply of the host, and the plug of the machine head (the part with wrench) must be removed. Preheat separately before next use. As the organic fertilizer production equipment is heavy machinery, the corresponding operation procedures and production projects must be strictly observed when operating the organic fertilizer granulation equipment to ensure the safety of production. When installing, pay attention to whether the host is vertical to the ground. After installation, first check whether the screw of the machine is loose and whether the air box of the main unit door is fixed. If there is any looseness, please strengthen it to avoid accidents.