Many people confuse organic fertilizer with organic carbon fertilizer and think that applying organic fertilizer is to supplement organic carbon. In fact, they differ greatly in water solubility and organic component functional groups.

Difference between carbon based fertilizer and organic fertilizer

Organic fertilizer generally refers to the carbonaceous organic materials processed from animal manure, animal and plant residues and animal and plant product residues through the organic fertilizer production line. The main raw materials of organic fertilizer are feces and straw, which are treated by a dumper and fermented and decomposed.

Although the carbon content of organic fertilizer is large, its water solubility is generally less than 10%, mostly about 3%, so the effectiveness of carbon is very low. It is difficult for crops to supplement carbon nutrition.

Organic carbon fertilizer refers to a fertilizer with strong water solubility, containing organic carbon compounds such as sugar, alcohol, acid (including humic acid) and easy to be absorbed by plants.

Find machines for carbon based fertilizer, go to https://organicfertilizermachines.com/compound-fertilizer-production-line/

1. At present, organic carbon fertilizer is classified according to chemical types, including organic acids, such as acetic acid, propionic acid, amino acid, etc; Sugars, such as monosaccharides, disaccharides and polysaccharides; Alcohols, such as ethanol, propanol and aldehydes.

2. According to the existing state, it can be divided into solid state, liquid state and gas state.

3. According to the structural complexity, it can be divided into simple carbon nutrients, such as monosaccharide, acetic acid, amino acid, etc; Compound carbon nutrients, such as humic acid, polysaccharide, hormone, polypeptide, vitamin, etc.

Applying organic carbon nutrients with complex structure directly to crops can save light energy and have more obvious fertilizer effect. Among them, humic acid and amino acid peptides with complex results are high-end products.

Find mchines to make organic fertilizer, welcome go to https://organicfertilizermachines.com/organic-fertilizer-production-line/

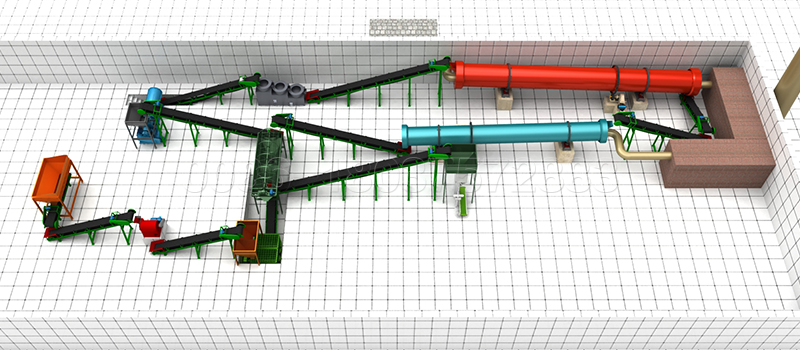

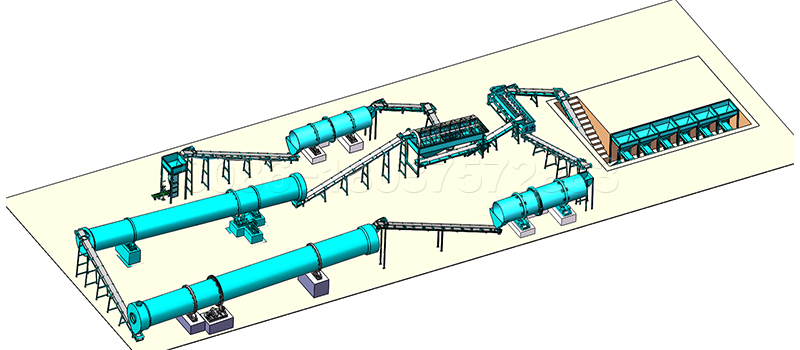

Production process of carbon based fertilizer

The production process of carbon based fertilizer can be divided into fermentation treatment and chemical degradation treatment. Among them, humic acid and fulvic acid produced with lignite as raw material and high-efficiency chemical degradation technology have high water solubility, no flocculation in hard water and high physiological activity.

It is a high-end organic carbon fertilizer. We provide carbon based fertilizer production process, NPK fertilizer production process and organic fertilizer production line according to user needs.

Want to find machines to make different types of fertilizers, welcome go to https://organicfertilizermachines.com/