1. Without adding any wetting agent, the material is compressed by the pressure of roller granulator to ensure the purity of raw material.

2. The compound fertilizer production line for npk granulation has the advantages of short process, low energy consumption and high yield.

3. The dry powder is granulated directly without subsequent drying process, which is more conducive to the connection and transformation of the existing production process.

4. The increase of bulk density is more significant than other granulation methods. It is especially suitable for increasing the proportion of products.

5. Flexible operation, suitable for a variety of raw materials, high output, low energy consumption, and can adjust the size of extrusion pressure by adjusting the hydraulic pressure.

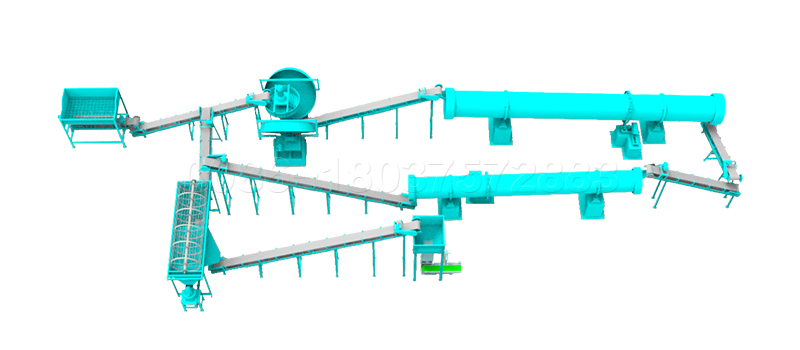

The compound fertilizer production line is equipped with double roll granulator, which has the advantages of short process flow, low energy consumption and large output. The dry powder is granulated directly without subsequent drying process, which is more conducive to the connection and transformation of the existing production process.

The increase of bulk density is more significant than other granulation methods. It is especially suitable for increasing the bulk density of products. It is flexible in operation and can be used in a wide range. The extrusion force can be adjusted by hydraulic pressure.